davidhusker

Members

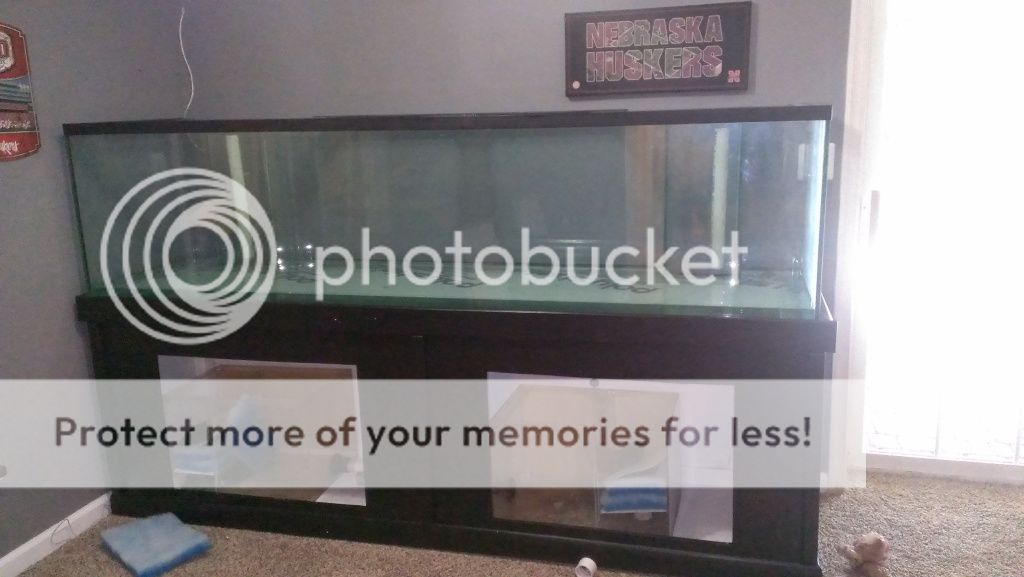

Yesterday morning I tried to tackle the task of moving this tank from my garage to my basement. I built the cart it is sitting on with 2x4 and some 5" swivel wheels. I was not really sure if it would hold up, as it had already broken once when we picked this tank up.

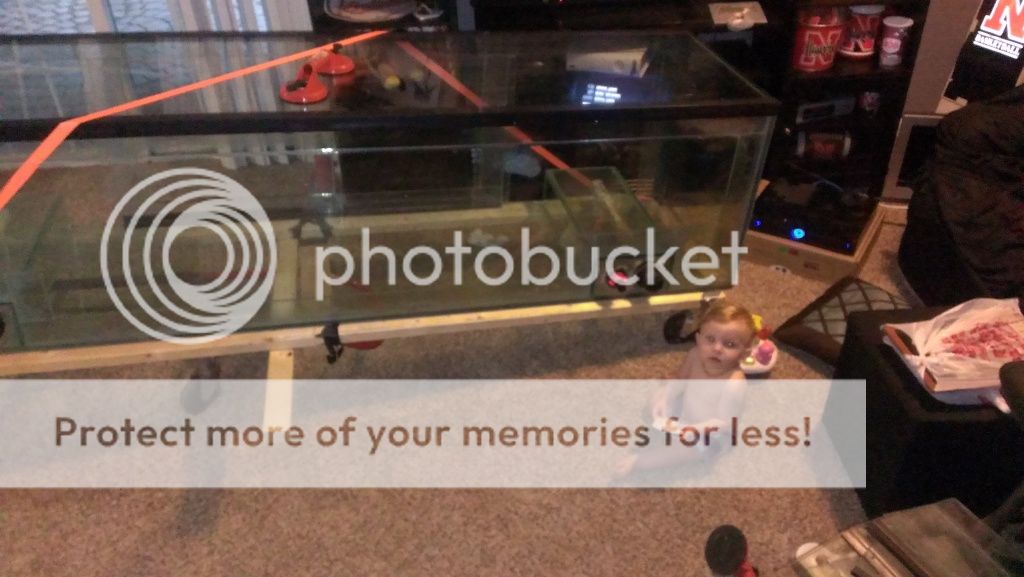

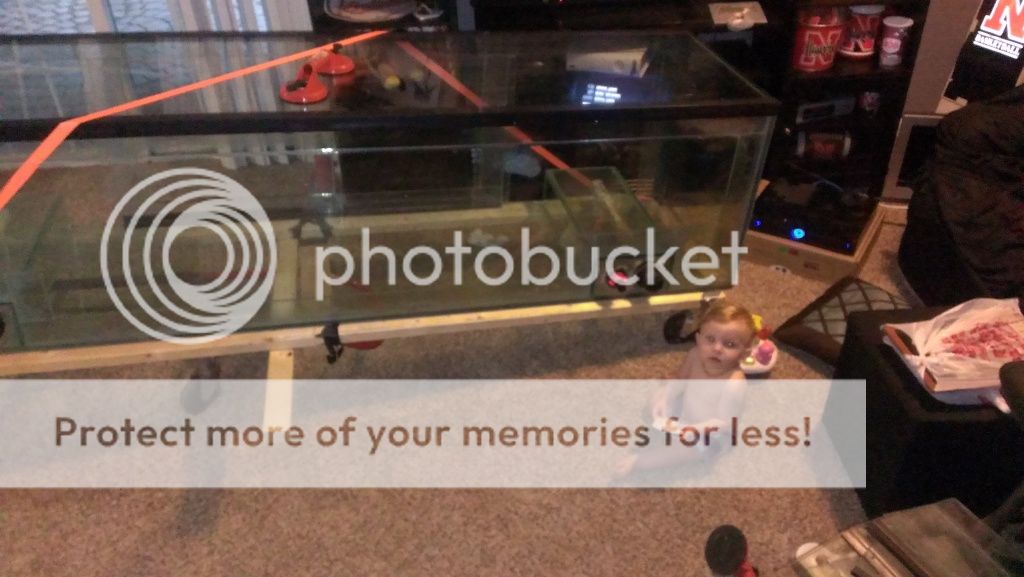

With just myself and my wife I pushed it out of the garage and everything was going smoothly until we hit grass. The wheels immediately dug into the ground and popped the screws out of the wood essentially ripping off a wheel. I had figured this was going to happen, but wanted to try it anyhow. So because I couldnt lift it from the ground by myself I did what any other american would do and used a car jack to lift it enough to fit my dolly underneath. Remember nothing is touching glass, the original "cart" almost acted like a wood crate around the tank so it worked out. After about 30-40 mins I got dollys under each end and off we pushed through the grass. Since carts dont just magically turn I had to stop every 5 feet or so pulling the carts to turn them. It was a crazy mess but we finally ended up in the house. I am having a couple friends come by Saturday to help get it on the stand safely.

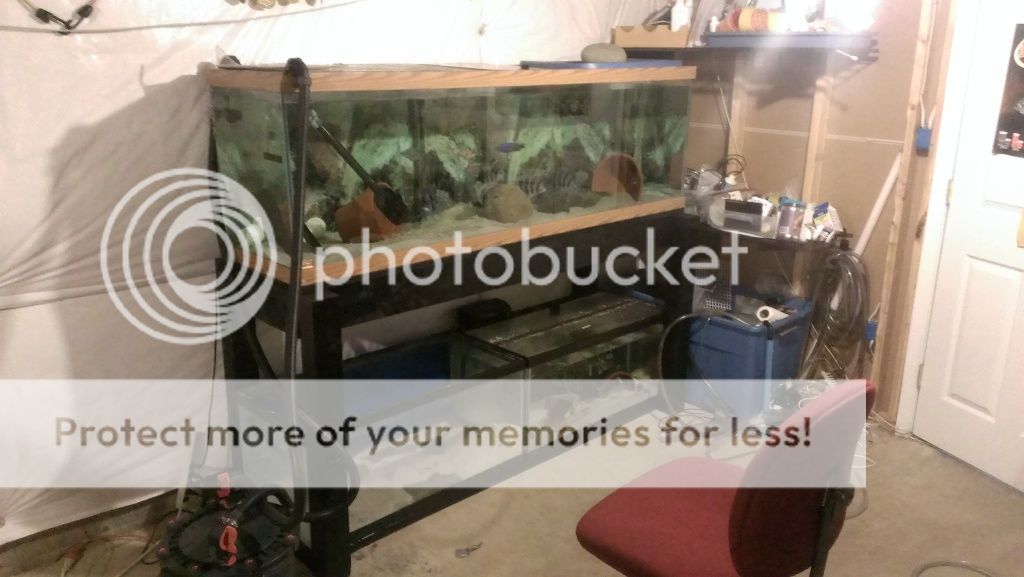

Basements filling up with fish toys now..

Also had my little helper. I keep telling my wife it is his swimming pool and not a fish tank.

I have a little bit more to do once it is on the stand and one more trip to home depot to get some tubing and pvc and attach the pumps up. Then I will test fill and keep you all updated as I go. I got the 7ft 210 sold and out of the house. Soon I will be moving the 180 back into the storage/fish room after this 250 is done.

With just myself and my wife I pushed it out of the garage and everything was going smoothly until we hit grass. The wheels immediately dug into the ground and popped the screws out of the wood essentially ripping off a wheel. I had figured this was going to happen, but wanted to try it anyhow. So because I couldnt lift it from the ground by myself I did what any other american would do and used a car jack to lift it enough to fit my dolly underneath. Remember nothing is touching glass, the original "cart" almost acted like a wood crate around the tank so it worked out. After about 30-40 mins I got dollys under each end and off we pushed through the grass. Since carts dont just magically turn I had to stop every 5 feet or so pulling the carts to turn them. It was a crazy mess but we finally ended up in the house. I am having a couple friends come by Saturday to help get it on the stand safely.

Basements filling up with fish toys now..

Also had my little helper. I keep telling my wife it is his swimming pool and not a fish tank.

I have a little bit more to do once it is on the stand and one more trip to home depot to get some tubing and pvc and attach the pumps up. Then I will test fill and keep you all updated as I go. I got the 7ft 210 sold and out of the house. Soon I will be moving the 180 back into the storage/fish room after this 250 is done.