Instructions:

1) I bought the Styrofoam 1st with the intention of making a background using concrete as I mentioned above. However, I changed that idea when I learned how many water changes I would have to perform due to an increase in pH caused by the concrete.

2) My 1st priority was that I didn’t want to sacrifice much tank space so I used a maximum of 2 inches (thick) Styrofoam.

Below is a list of the materials needed:

1) Styrofoam. (If tank space is important to you, then you can use 2†thick sheets from Home Depot if you’d like. If you’re careful with the knives, you can carve shapes that stand out.)

2) Jagged edge knife with 4-5†blade.

3) Set of hobby knives.

4) Pack of disposable latex gloves.

5) Tape measure.

6) Gravel or river rock of your choice.

7) Aquarium safe silicone. LOTS OF IT!! (If your local aquarium store doesn’t have it, then you can get it from E-Bay)

8) Rags.

9) Bernzomatic blow torch. ($13 at Home Depot)

10) A few decorative rocks. No greater than 1 lb each.

11) 1 can of “Great Stuff†(Spray Foam – Again, at Home Depot)

12) 2†paint brush (optional). (I had better success with my hands – use gloves)

13) Artificial plants (optional)

14) And like those before me, lots of patience.

Instructions:

1) First cut the dimensions of the Styrofoam to conform to the size of the rear-glass of your tank. Make sure you divide the foam into at least 2 parts. I say this because you can break the background due to the weight of the gravel and the strength of the Styrofoam. It is best managed when your background is cut into parts that are 3 ft or less.

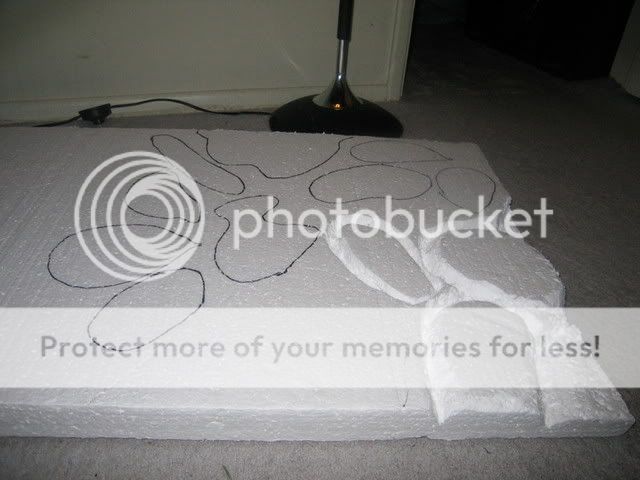

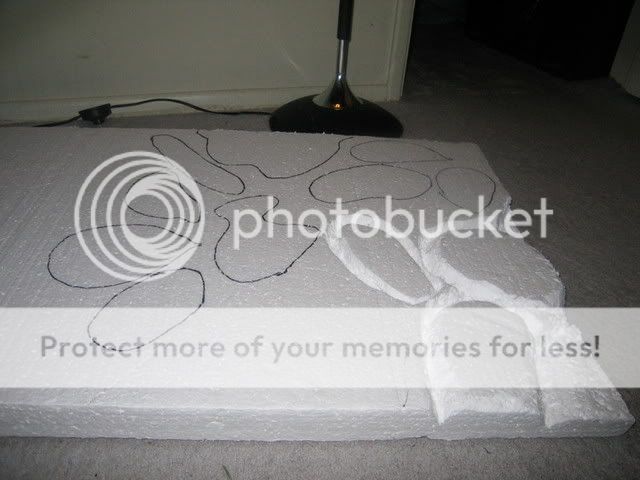

2) You can begin to carve the Styrofoam any way you’d like. Be careful not to carve too deep. Finish all of the carving before moving to step 3.

3) Using the blow torch, begin to heat the carved areas along the Styrofoam. As mentioned in other DIY backgrounds. Use caution, as the foam is flammable and you can burn a hole in it very easily.

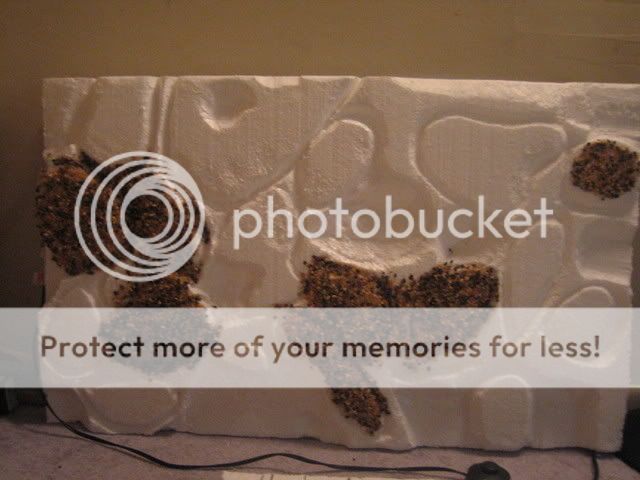

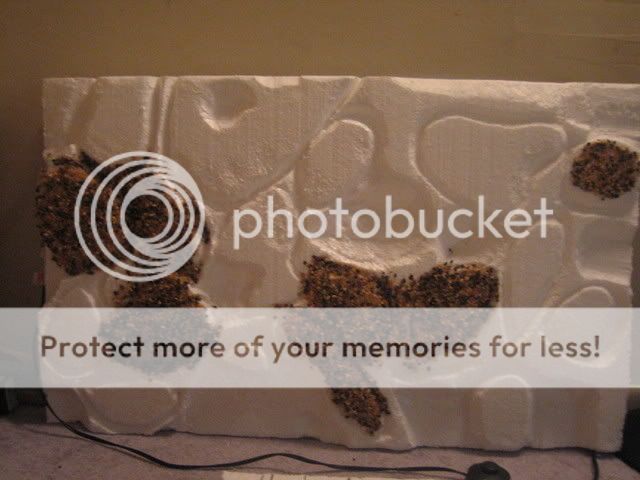

4) Paint on the silicone at least 1/8 inches thick over a surface area of 1 ft2 at a time.

5) Pour the gravel/rocks on the silicone.

6) Repeat steps 4 and 5 until completely covered.

7) After the silicone is cured (48 hrs), stand the background upright to allow all of the loose gravel to fall off.

8) More than likely you will need to fill in gaps from fallen or loose gravel. So please be patient.

9) If you fancy plants, use a knife and slice in 1 inch deep gashes at 45° angles. Slide branches in the slots and then silicone it shut. They will be more secure and difficult for cichlids to remove them by pulling and tugging.

10) If you have any gaps between your two pieces of background you can use a can of Great Stuff to fill it. Then repeat steps 4 and 5.